- Home

- About Us

About Us

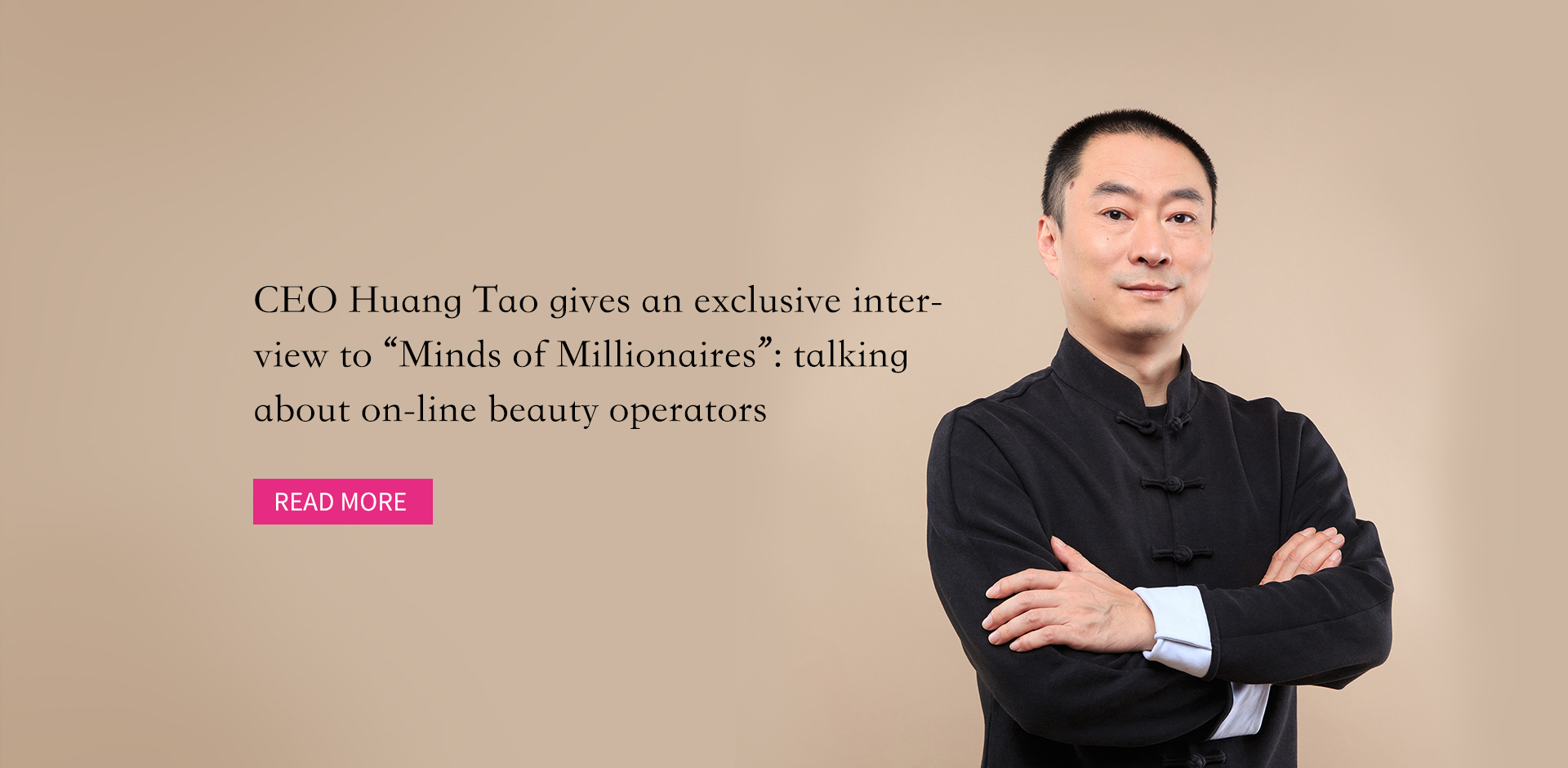

Lily & Beauty,the leading provider of on-line cosmetics marketing and retailing services in China, authorized by and cooperating with the international top cosmetics groups, has united with more than 50 renowned international brands, pledging to make the beauty go on.

- Stores

- ESG

- News

- Investor Relations

- Join Us

- Contact Us